As industries continue to strive for faster and more cost-efficient product development, 3D CAD Modeling and Simulation have become indispensable tools in machine innovation. These technologies allow engineers to visualize, prototype, and test mechanical systems with remarkable accuracy—before any physical materials are used. The integration of mechanical 3D modeling and CAD virtual prototyping helps reduce design flaws, optimize functionality, and significantly accelerate time-to-market.

The Role of 3D CAD Modeling and Simulation in Machine Development

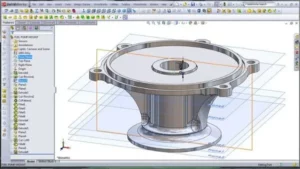

3D CAD (Computer-Aided Design) modeling enables the creation of detailed virtual representations of mechanical parts and assemblies. When paired with simulation, these models transform into interactive systems that behave like their real-world counterparts under various operational conditions.

This digital-first approach delivers critical benefits to machine manufacturers:

- Enhanced design accuracy: Engineers can fine-tune dimensions and tolerances in a virtual environment.

- Reduced prototyping costs: Fewer physical prototypes are required thanks to CAD virtual prototyping.

- Faster development cycles: Design validation is achieved early, speeding up progression to manufacturing.

- Improved performance testing: 3D machine simulation allows stress, load, thermal, and motion analyses before product assembly.

Mechanical 3D Modeling: The Foundation of Design Accuracy

Mechanical 3D modeling forms the core of any innovative machine project. It provides precise geometric data, enabling engineers and designers to visualize and assemble complex machinery before fabrication. With sophisticated CAD platforms, detailed components can be modeled, assembled, and checked for interference, clearances, and mobility.

Services like machine design and drafting from IDEA Group ensure that every mechanical aspect is accounted for, reducing the risk of errors in production. Whether it’s a single-component motor housing or an integrated robotics assembly, 3D models lay the groundwork for reliable performance and structural integrity.

Virtual Prototyping and Real-time Simulation Accuracy

3D machine simulation introduces realistic, testable interactions between parts, simulating motion, load impact, and dynamic forces on virtual assemblies. Through simulation software, engineers can discover hidden design flaws, unforeseen material weaknesses, or kinematic failures all before manufacturing begins.

Simulation variability further supports design optimization. Variables such as speed, torque, pressure, and temperature are adjusted within the CAD virtual prototyping environment to analyze their effects instantly. Ultimately, this delivers exceptional design validation during early-stage development, saving time and money downstream.

Applications Across Diverse Industrial Sectors

Adoption of 3D CAD Modeling and Simulation spans a wide range of industries including:

- Automotive manufacturing: For modular part integration and motion analysis.

- Automation and robotics: Precise modeling for high-tolerance systems and joint movement simulation.

- Pharmaceutical equipment design: Ensuring sanitary flow systems using accurate internal geometry modeling.

- Food and beverage machinery: Testing material resistance to cleaning agents and wear over time.

Real-world applications by experts like Che Tao May IDEA demonstrate how simulation-driven design delivers success in industrial-scale deployments.

Elevating Smart Manufacturing with CAD Precision

With the rise of Industry 4.0, machine builders are embracing digital integration where real-time data links future simulation with current production. This intelligent feedback loop—when combined with precise mechanical 3D modeling—creates adaptive systems that can self-optimize for performance and efficiency. Solutions provided by IDEA Tech Mart further leverage automation with flexible machine configurations built straight from CAD databases.

By eliminating guesswork and emphasizing data-informed decisions, 3D CAD Modeling and Simulation pave the road to scalable innovation, reducing waste and increasing yield at every manufacturing level.

Partnering with Experts for Maximum Impact

Unlocking the full potential of 3D machine simulation and CAD virtual prototyping requires experienced partners who understand the intricacies of mechanical design. IDEA offers comprehensive engineering support—from initial concept sketches to complete 3D design validation and simulation.

With deep industry experience and a commitment to precision, IDEA ensures your machine designs are both innovative and production-ready.

Embrace the future of machine design through 3D CAD Modeling and Simulation. Improve reliability, reduce cost, and innovate faster with a trusted leader. Contact IDEA today to collaborate on your next industrial breakthrough and elevate your engineering potential.